Waugh produces face shield parts to help medical professionals

Published 9:51 am Tuesday, April 28, 2020

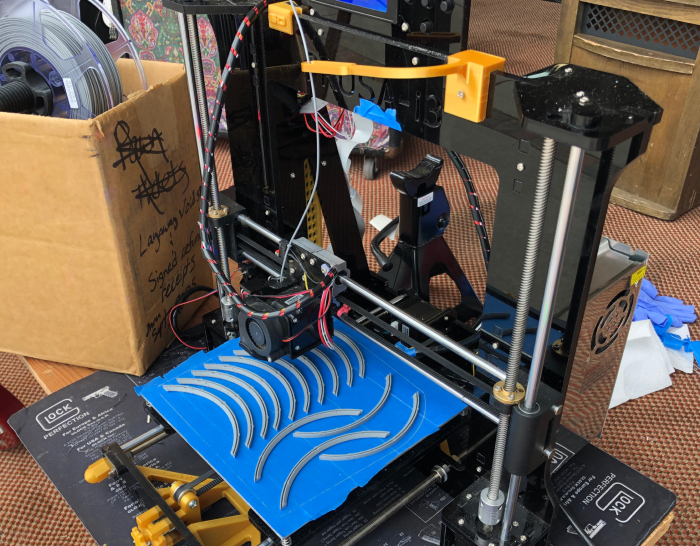

- David Waugh is utilizing his 3-D printers to produce key components needed to create face shields.

|

Getting your Trinity Audio player ready...

|

David Waugh, manager of Top Dollar Jeweler & Loan in downtown Albemarle, wanted to help those affected by the coronavirus pandemic but he didn’t know how.

“It was hard to come up with what I could do,” he said.

But with medical professionals around the country in need of personal protective equipment, the Mount Pleasant resident went to work utilizing his two 3-D printers, one at home and one at work, to produce key components needed for face shields.

His service originated when Waugh received an email from a group he’s associated with called We The Builders, asking for help in producing face shields that would be distributed to various hospitals and health care organizations in the Baltimore area, where the group is based. The group produces giant crowd-sourced sculptures out of hundreds of small parts sent to them by people around the world with access to 3-D printers, according to its website.

To fill the shortage of personal protection equipment in hospitals around the country, people with 3-D printers connected to the group have been downloading files from Prusa Research, a Czech-based tech company that designs 3-D printers, to print different face shield parts, Waugh said. He has been printing headbands and a piece at the bottom of the shield that helps it to stay curved. Once the parts are shipped to Baltimore, We The Builders assembles the shields and sends them to the the medical professionals on the front lines.

Waugh has to supply the raw plastic materials, which he orders online from Amazon and Walmart.

Waugh is also sending shield parts to a local group called Charlotte Medical Emergency Device Innovation, which was recently created to produce face shields for healthcare workers in Charlotte. He’s dropping them off at two local homes along with Charlotte Latin School, which formed the group along with UNC Charlotte.

Charlotte MEDI’s goal is to deliver more than 15,000 face shields a week to local healthcare workers utilizing its network of 3-D printers and local manufacturing companies, according to its website.

He said it takes about four and a half hours to produce the headband and the shield piece and his printers run about 17 hours a day.

“I’m just doing what I can,” he said. “If they (medical workers) are putting themselves at a greater risk to help others, the least I could do is donate my printers, filament and time to help them.”